We recently collaborated with major plastic packaging company to enhance the production of their container jars. This partnership led to significant improvements in product quality, cost reduction, and increased productivity.

🔧 Challenge

The company was using masterbatch at 4% instead of the company directive of 2%, causing waste due to poor mixing and aesthetic defects.

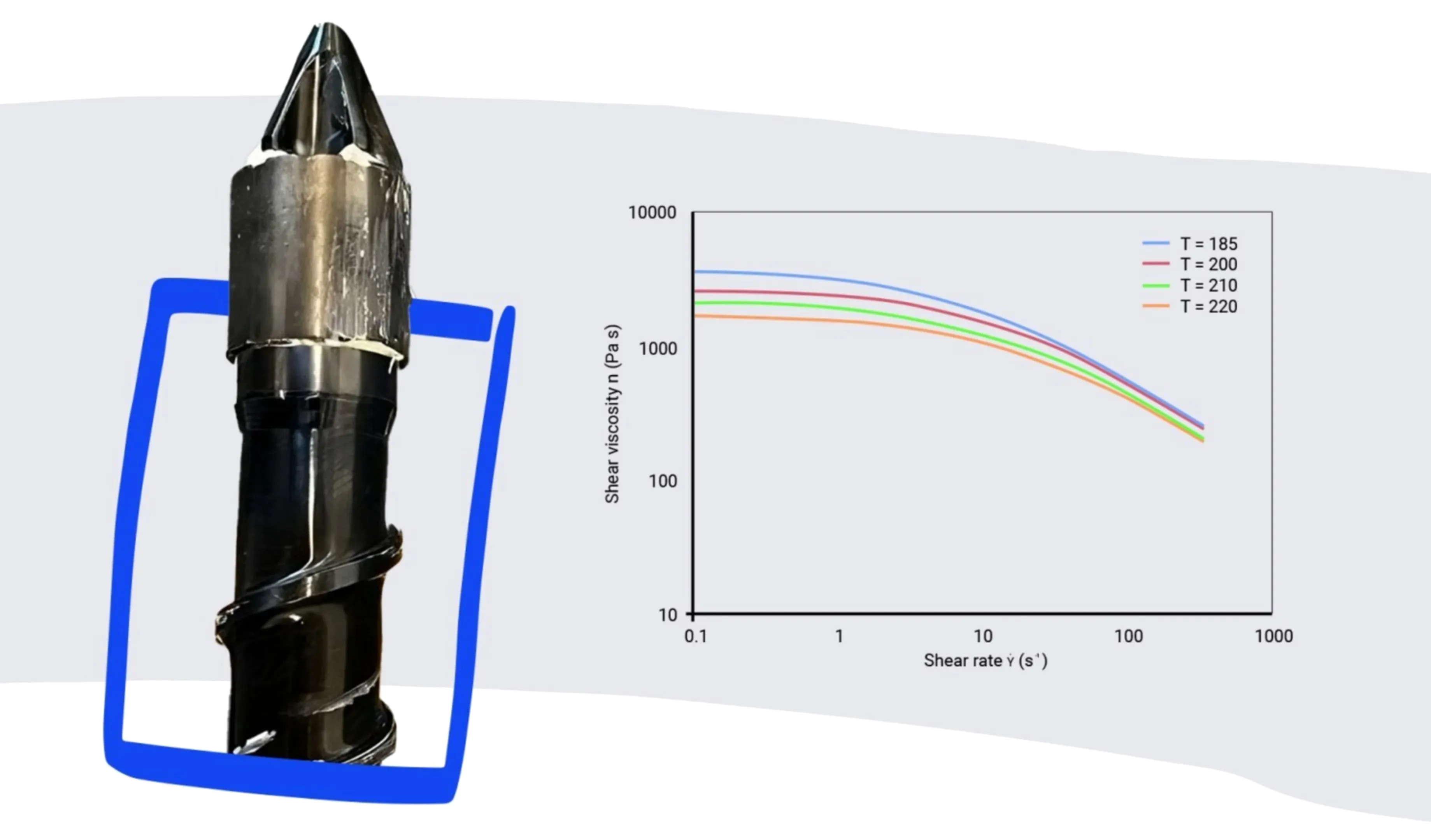

🚀 Solution

By utilizing the Maxi Melt pack screw with a double mixer, we achieved uniform plastification of the PP polymer, greatly improving the product's aesthetic quality.

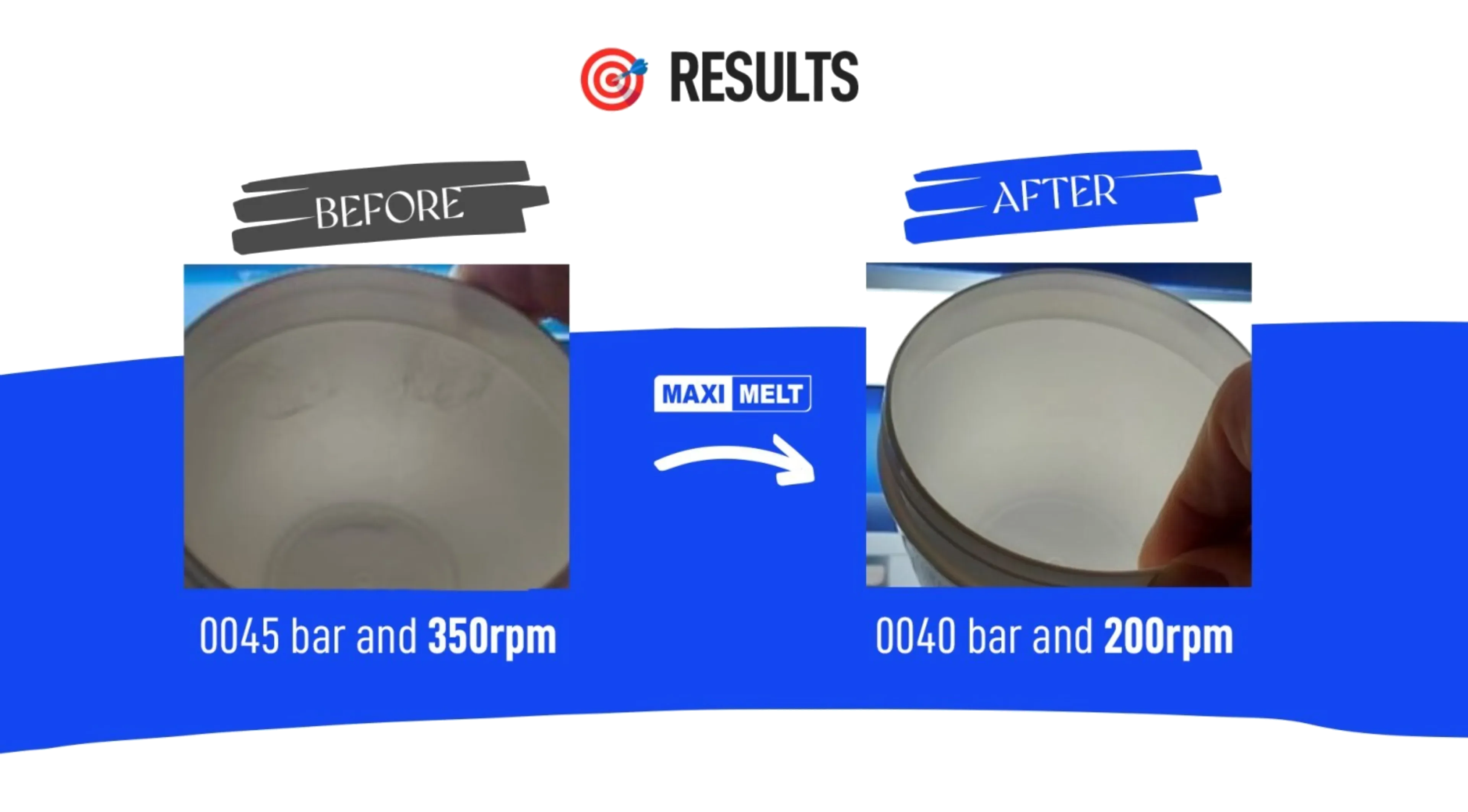

🎯 Results

- Reduced masterbatch usage from 4% to 2%

- Decreased screw speed from 350 rpm to 200 rpm

- Enhanced aesthetic quality of the product

We are proud to have helped our partner achieve their production and quality goals, once again demonstrating the effectiveness of Maxi Melt solutions in the plastification sector.

en

en nl

nl de

de it

it es

es