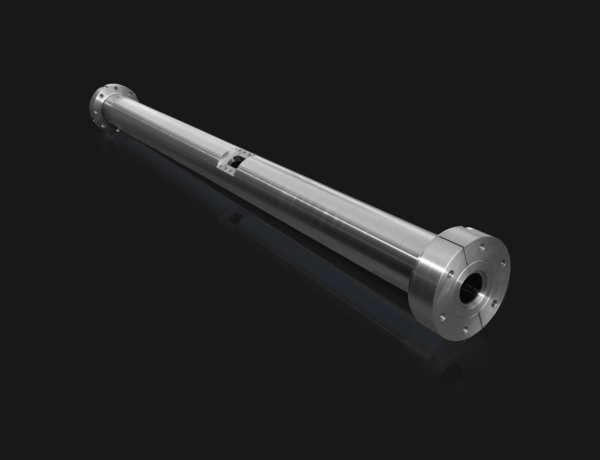

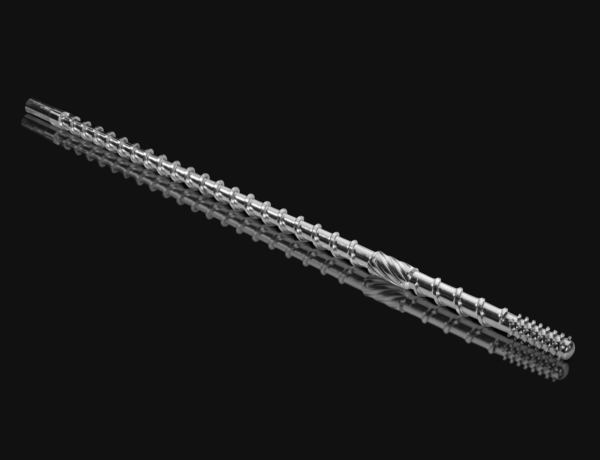

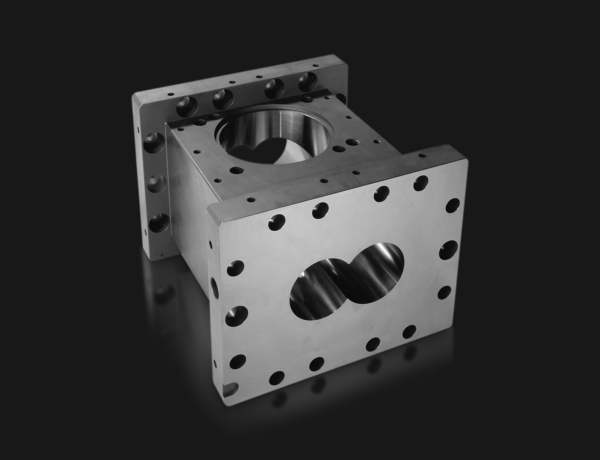

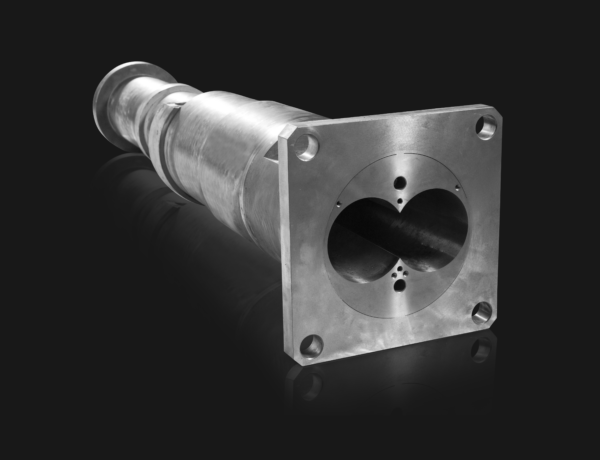

Nitrided cylinders

We supply complete twin counter rotating cylinders. Based on our large experience we can recommend the proper type of solutions to minimize wear.

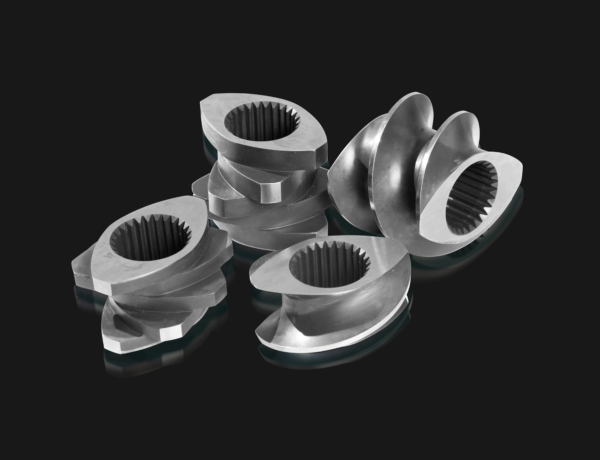

Cylinders lined with Bimetallic liners

We deliver new twincylinders according to OEM’s specification and quality with bimetallic liners with differnt alloy selection.

Bimetallic liner (replacement)

For extreme wear we recommend bimetallic liners to be fitted in a outerhousing. In a lot of cases we can upgrade old worn nitrided cylinders and fit bimetallic liners.

The advantage of our twin cylinders

Up to date machinery and CAD CAM facilities make it possible to manufacture high quality complex products with tight tolerances with a high surface finish suitable to withstand wear and or corrosion conditions.

Materials for twin cylinders

Choosing the right cylinder material is important to have the right performance to reduce wear and corrosion.

-

MM Code

Base Material

Treatment

Abrasive Wear Resistance

Corrosive Wear Resistance

-

MM41Quenced and TemperedNitriding++

-

MM34Quenced and TemperedNitriding++

Materials for twin cylinders

Choosing the right bimetallic liner material is important to have the right performance to improve wear and corrosion resistance.

-

Type

Alloy

Alloy components

Hardness [HRC]

(a) Hardness of matrix, tungsten carbides have a hardness of 89 HRC.Abrasion resistance

(x good) to (xxxxx excellent)Corrosion resistance

(x good) to (xxxxx excellent) -

KB 100FeNi - C - B58 - 65+++

KB 100FeNi - C - B58 - 65+++ -

KB 109Fe - CrNi - Mo - Cu - C - B58 - 65++++++

KB 109Fe - CrNi - Mo - Cu - C - B58 - 65++++++ -

KB 200Ni - CoCr - Mo - B58 - 65+++++

KB 200Ni - CoCr - Mo - B58 - 65+++++ -

KB 300NiCr - Ni - Co - B - W58 - 65++++++++

KB 300NiCr - Ni - Co - B - W58 - 65++++++++ -

KB 350NiCr - Si - B - W58 - 65+++++++++

KB 350NiCr - Si - B - W58 - 65+++++++++

-

TypeKB 100

-

AlloyFe

-

Alloy componentsNi - C - B

-

Hardness [HRC]58 - 65

-

Abrasion resistance++

-

Corrosion resistance+

-

TypeKB 109

-

AlloyFe - Cr

-

Alloy componentsNi - Mo - Cu - C - B

-

Hardness [HRC]58 - 65

-

Abrasion resistance+++

-

Corrosion resistance+++

-

TypeKB 200

-

AlloyNi - Co

-

Alloy componentsCr - Mo - B

-

Hardness [HRC]58 - 65

-

Abrasion resistance+

-

Corrosion resistance++++

Example twin cylinder

Based on all material and treatment options we selected some examples for twin counterrotating cylinders.

Twin cylinder Nitrided

Contact us-

Alloy1,8509

-

Alloy componentsCr AI

-

Hardness [HRC]950-1100 Hv (65-67 Hrc)

-

Size [mm]Ø90

-

Abrasion resistance+

-

Corrosion resistance+

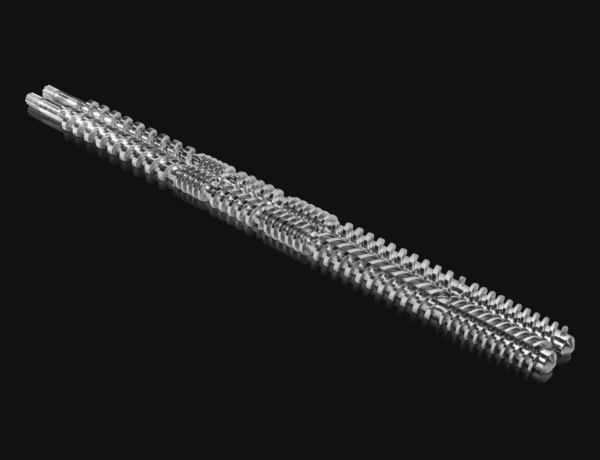

Twin cylinder KB100/109

Contact us-

AlloyKB 109

-

Alloy componentsNi - Mo - Cu - C - B

-

Hardness [HRC]64 - 69

-

Size [mm]Ø 75

-

Abrasion resistance+++

-

Corrosion resistance+++

Twin cylinder KB300/KB350

Contact us-

AlloyBimetallic KB 350

-

Alloy componentsCr - Si - B - W

-

Hardness [HRC]60-66

-

Size [mm]Ø 115

-

Abrasion resistance+++++

-

Corrosion resistance++++

Discover more products

Other products for injection and extrusion can be found below by clicking on the pictures more information is shown.

en

en nl

nl de

de it

it es

es