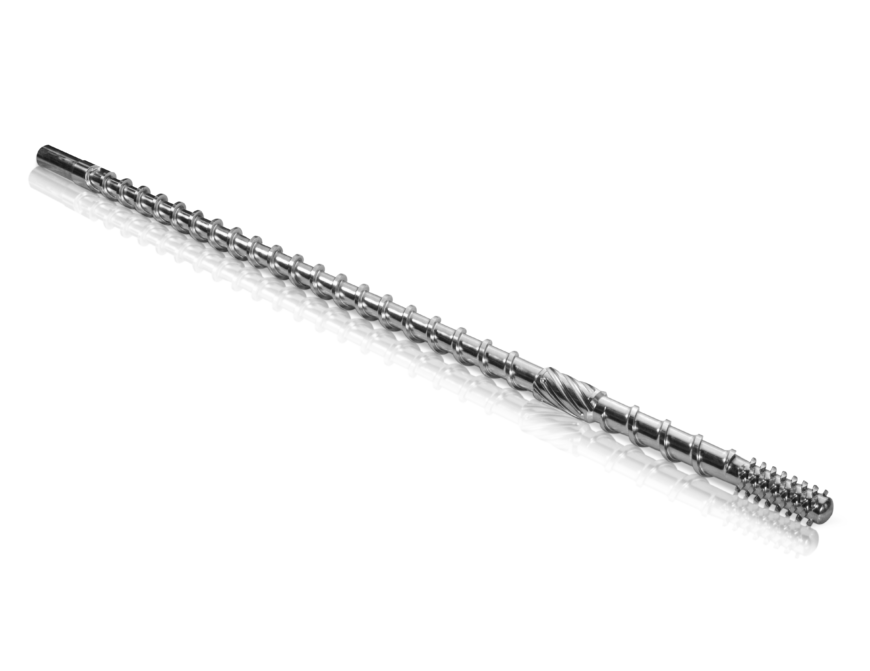

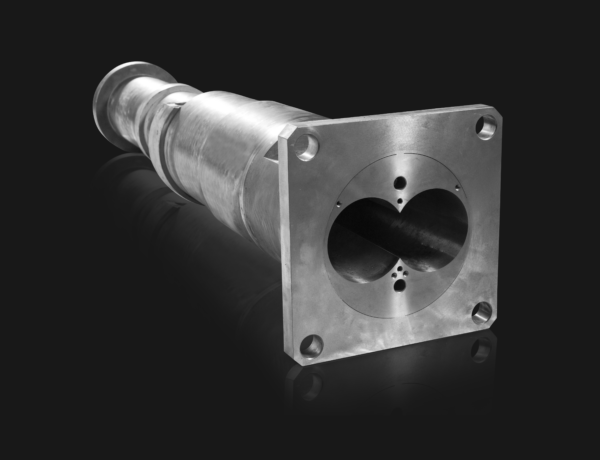

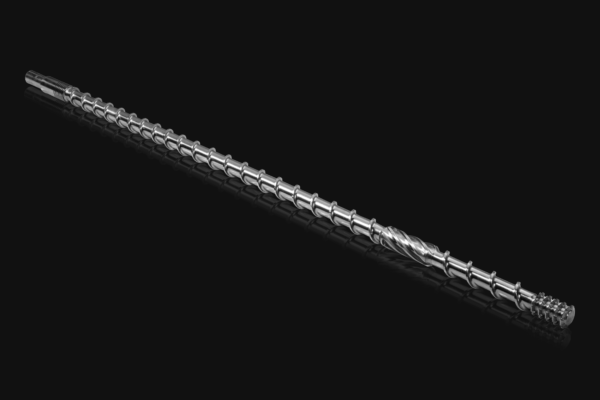

Single screws

We can supply a complete range of extrusion screws. Based on our large experience we can recommend the proper type of steel and surface treatment to minimize wear. According to customer’s needs we can propose nitriding steel, stainless steel, tool steel and also sintered steels (CPM/PM).

Screws according to OEM’s specifications

We deliver screws according to OEM’s specification.A screw is the heart of the process and determines the the productivity and the quality of the molded parta. For this reason we can deliver screws with a Maxi Melt design that can help you to optimise your production.

Deliver better surface

Our screws can be delivers with all kind of treatmenst to improve surface conditions and to improve plasticizing. A beter surface finish will improve plasticizing and reduce reject rate. All these improvements are just standard for us, so that we can bind the fulfilment of these objectives to the purchase of the screw.

The advantage of our extrusion screws

Up to date machinery and CAD CAM facilities make it possible to manufacture high quality complex products with tight tolerances from different kind of materials to be selected from case to case with a high surface finish suitable to withstand wear and or corrosion conditions

Materials for plasticizing screws

Choosing the right screw material is important to have the right plasticizing performance in order to reduce wear and corrosion problems.

-

MM Code

Base Material

Treatment

Abrasion resistance

(x good) to (xxxxx excellent)Corrosion resistance

(x good) to (xxxxx excellent) -

MM31Quenced and TemperedNitriding++

-

MM41Quenced and TemperedNitriding++

-

MM34Quenced and TemperedNitriding++

-

MM39Quenced and TemperedHardening++++

-

KPM1Powder Metallurgy SteelHardening++++++++

-

KPM2Powder Metallurgy SteelHardening++++++++++

-

MM CodeMM31

-

Base MaterialQuenced and Tempered

-

TreatmentNitriding

-

Abrasion resistance+

-

Corrosion resistance+

-

MM CodeMM41

-

Base MaterialQuenced and Tempered

-

TreatmentNitriding

-

Abrasion resistance+

-

Corrosion resistance+

-

MM CodeMM34

-

Base MaterialQuenced and Tempered

-

TreatmentNitriding

-

Abrasion resistance+

-

Corrosion resistance+

-

MM CodeMM39

-

Base MaterialQuenced and Tempered

-

TreatmentHardening

-

Abrasion resistance+

-

Corrosion resistance+++

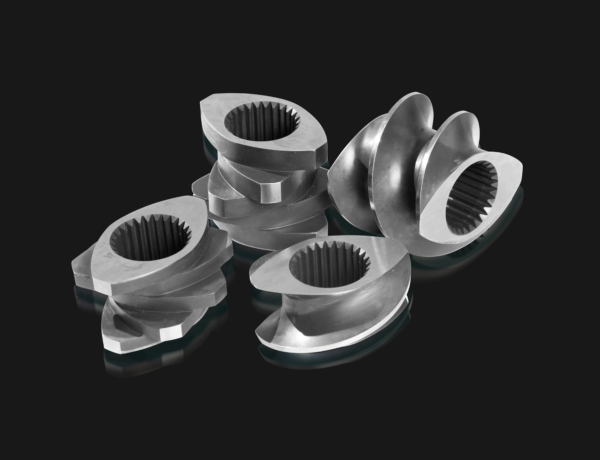

Welding materials for the screw flights

For larger screw sizes we often use nitrided materials with the flighttips welded welded with different materials options. This creates wear/corrosion protection or improves friction/lubrication.

-

MM CODE

FLIGHT ARMORING

TECHNOLOGY

ABRASIVE WEAR RESISTANCE

CORROSIVE WEAR RESISTANCE

-

MM120Cobalt Base AlloyPTA++++++

-

MM50Iron Base AlloyTIG++++++

-

MM560Nickel Base AlloyPTA++++++++

-

MM570Nickel Base AlloyPTA+++++++++++

-

MM830Nickel Base AlloyPTA++++++++++

-

MM4900MolybdenumHVOF+++++++++

-

MM6000Tungsten CarbideHVOF++++++++++++

-

MM CODEMM120

-

FLIGHT ARMORINGCobalt Base Alloy

-

TECHNOLOGYPTA

-

ABRASIVE WEAR RESISTANCE+++

-

CORROSIVE WEAR RESISTANCE+++

-

MM CODEMM50

-

FLIGHT ARMORINGIron Base Alloy

-

TECHNOLOGYTIG

-

ABRASIVE WEAR RESISTANCE++++

-

CORROSIVE WEAR RESISTANCE++

-

MM CODEMM560

-

FLIGHT ARMORINGNickel Base Alloy

-

TECHNOLOGYPTA

-

ABRASIVE WEAR RESISTANCE++++

-

CORROSIVE WEAR RESISTANCE++++

-

MM CODEMM570

-

FLIGHT ARMORINGNickel Base Alloy

-

TECHNOLOGYPTA

-

ABRASIVE WEAR RESISTANCE++++++

-

CORROSIVE WEAR RESISTANCE+++++

-

MM CODEMM830

-

FLIGHT ARMORINGNickel Base Alloy

-

TECHNOLOGYPTA

-

ABRASIVE WEAR RESISTANCE+++++

-

CORROSIVE WEAR RESISTANCE+++++

Screw coatings

In most cases, these coatings reduce friction, improve plasticizing, or protect against corrosion.

-

Coatings

Surface Coating

Technology

Hardness µm

Thickness

Color

Friction Coefficient Ra

-

MMFCFlash ChromiumPlating58/60 HRC0,02/0,03 MMHigh Polishing0,17

-

MMTCThickness ChromiumPlating58/60 HRC0,10/0,15MMHigh Polishing0,17

-

MMCRNALCRNPvd2800-3200 HV2-8 µmViolet0,35

-

MMZRNZRNPvd2600-3100 HV2-4 µmClear Yellow0,45

-

MMTINTINPvd2000-2500 HV2-4 µmGold Yellow0,45

-

MMNOXCRNOXPvd2000-2500 HV2-4 µmIridescent Rainbow0,25

-

MMHDLCHDLCPvd5000 HV1-3 µmBlack Rainbow0,05/0,15

-

MMEXTHDLCArco2500 HV2-6 µmGrey0,3/0,4

-

CoatingsMMFC

-

Surface CoatingFlash Chromium

-

TechnologyPlating

-

Hardness µm58/60 HRC

-

Thickness0,02/0,03 MM

-

ColorHigh Polishing

-

Friction Coefficient Ra0,17

-

CoatingsMMTC

-

Surface CoatingThickness Chromium

-

TechnologyPlating

-

Hardness µm58/60 HRC

-

Thickness0,10/0,15MM

-

ColorHigh Polishing

-

Friction Coefficient Ra0,17

-

CoatingsMMCRN

-

Surface CoatingALCRN

-

TechnologyPvd

-

Hardness µm2800-3200 HV

-

Thickness2-8 µm

-

ColorViolet

-

Friction Coefficient Ra0,35

-

CoatingsMMZRN

-

Surface CoatingZRN

-

TechnologyPvd

-

Hardness µm2600-3100 HV

-

Thickness2-4 µm

-

ColorClear Yellow

-

Friction Coefficient Ra0,45

-

CoatingsMMTIN

-

Surface CoatingTIN

-

TechnologyPvd

-

Hardness µm2000-2500 HV

-

Thickness2-4 µm

-

ColorGold Yellow

-

Friction Coefficient Ra0,45

-

CoatingsMMNOX

-

Surface CoatingCRNOX

-

TechnologyPvd

-

Hardness µm2000-2500 HV

-

Thickness2-4 µm

-

ColorIridescent Rainbow

-

Friction Coefficient Ra0,25

Example screws

Based on all material and treatment options we selected some examples screw configuration versus polymer processing.

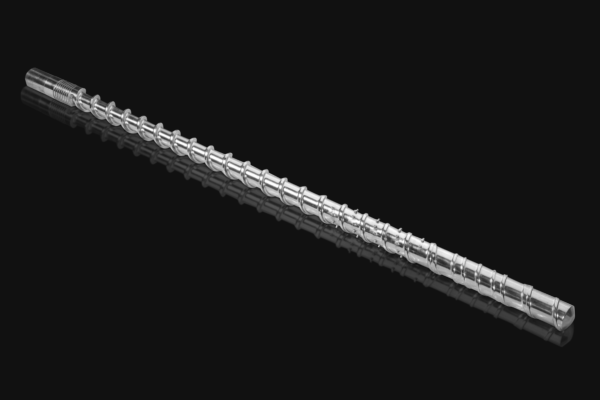

Extrusion 3 Zone screw with mixer for processing PP profiles

Extrusion screw 1

Contact us-

Alloy1,8509

-

Alloy componentsCr - AI

-

Hardness [HRC]950-1100 Hv (65-67 HRC)

-

Size [mm]Ø 60

-

Abrasion resistance+

-

Corrosion resistance+

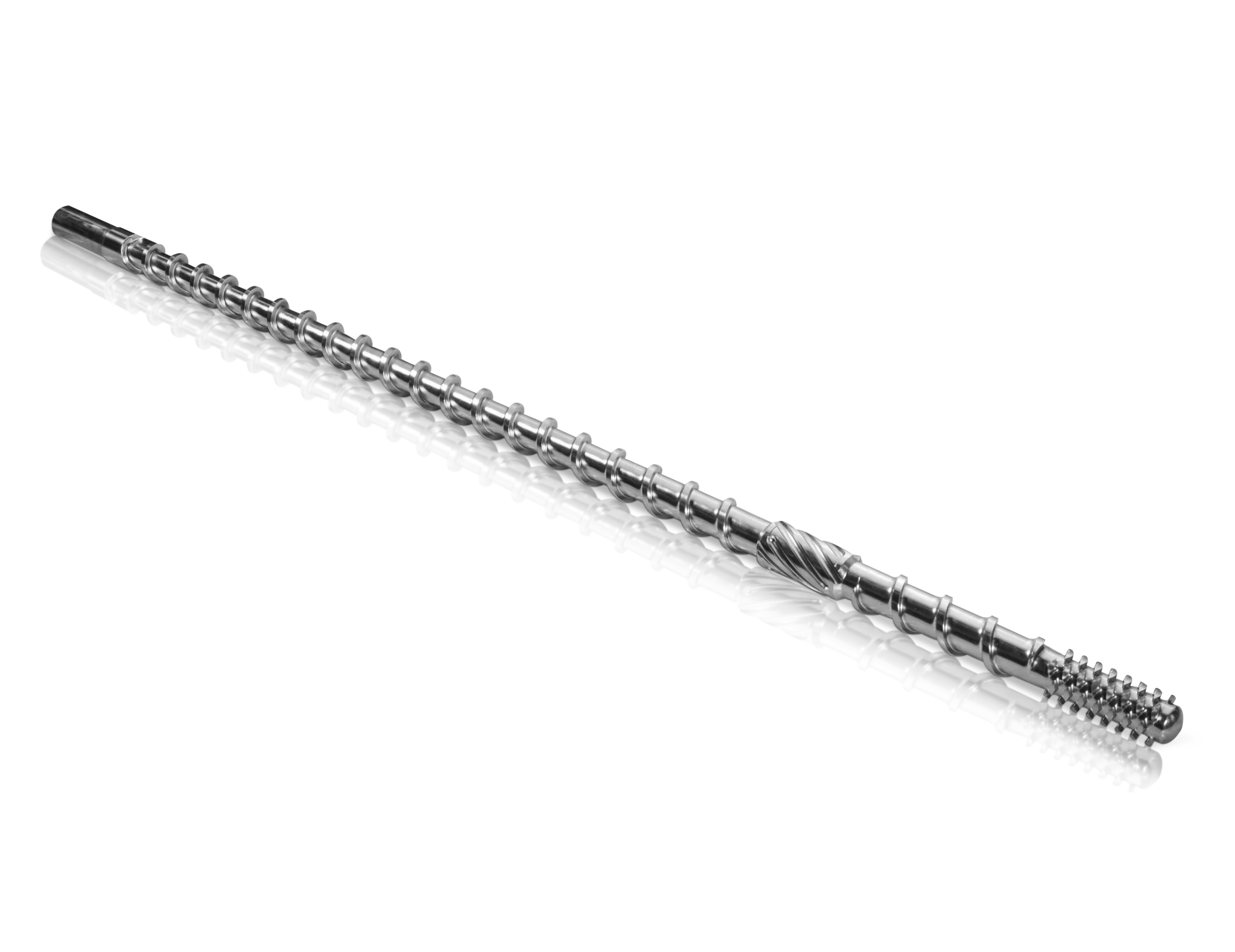

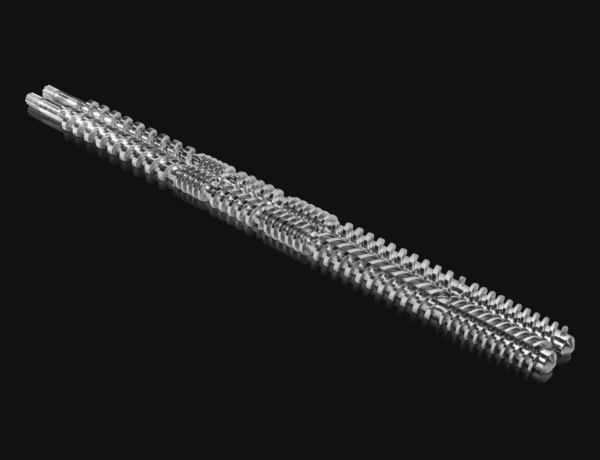

Extrusion screw with 2 mixers for processing LLDPE with masterbatch. Blowfilmapplication.

Extrusion screw 2

Contact us-

Alloy1,8550

-

Alloy componentsCr - AI

-

Hardness [HRC]950-1100 Hv (65-67 HRC)

-

Size [mm]Ø 75

-

Abrasion resistance+

-

Corrosion resistance+

Extrusion screw for processing rubber.

Extrusion screw 3

Contact us-

Alloy1,8509

-

Alloy componentsCr - AI

-

Hardness [HRC]950-1100 Hv (65-67 HRC)

-

Size [mm]Ø 60

-

Abrasion resistance+

-

Corrosion resistance+

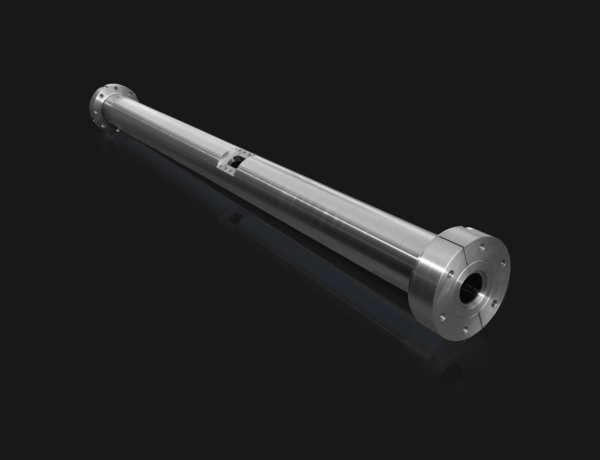

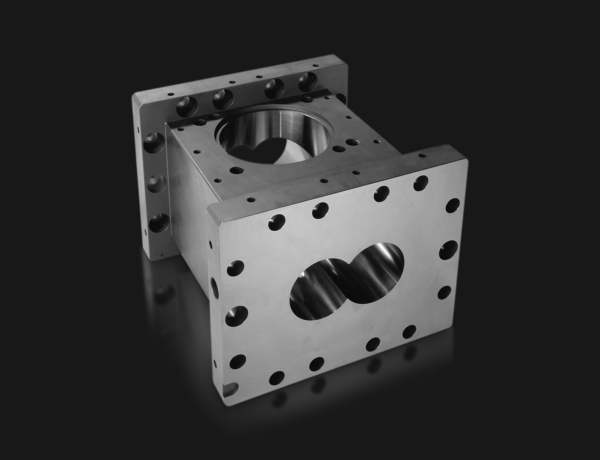

Discover more products

Other products for injection and extrusion can be found below by clicking on the pictures more information is shown.

en

en nl

nl de

de it

it es

es