Cost saving

Refurbishing can generate 30% or more costsaving aginst new parts.

Shorter delivery time

Repair is mostly faster than new so in critical situations reduce downtime of the machine if something is broken and not available on stock.

Choice of different welding materials

Material weld can be adjusted to current needs.

Cylinder Repair through larger a larger inner diameter

A worn cylinder, bimetallic or nitrided, can be repaired by honing the inner diameter to a larger diameter. In case of nitrided cilinders a new nitriding treatment shall be made with a depth of 0,4 ÷ 0,5 mm to ensure the necessary hardness. A honing operation must follow so that all dimensions are within the new oversized tolerances. In case of a bimetallic cylinder only the boring needs to be honed. No renitriding and honing is necessary. Of course the outer diameter of the screw, valve and eventually end cap inner diameter must be adjusted to the new (larger) dimension of the cylinder. This is a cheap but effective solution but has one disadvantage: the repaired cylinder and screw become non standard equipment and dedicate spare components shall be stored.

Cylinder repair with bushing

In special cases Injection cylinders can be repaired by reline the worn area with a liner which shall be longer as the screw stroke (5D) so the valve operate at the original nominal diameter. The liner can be made of nitrided steel, hardened steel but also of bimetallic alloy.

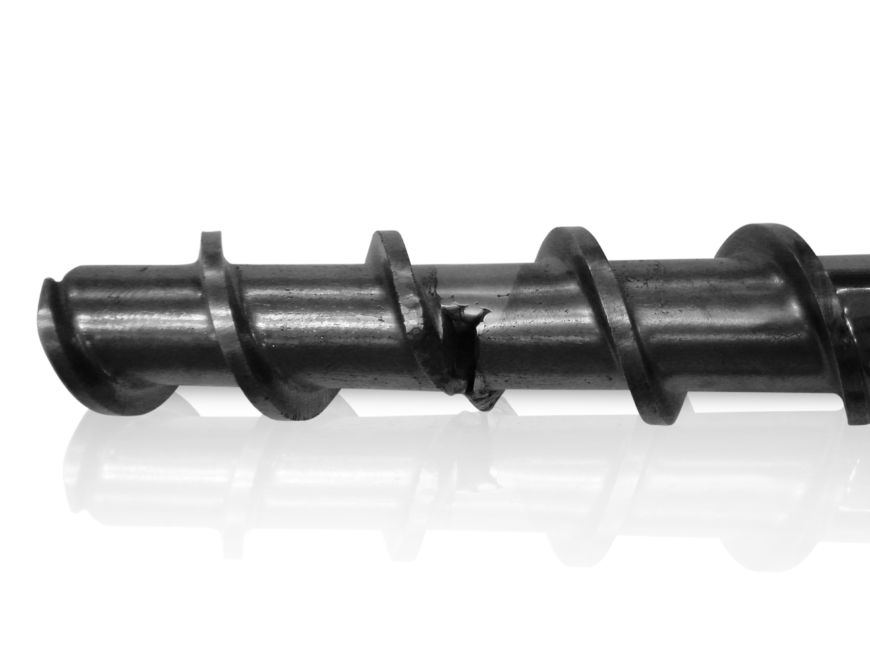

Repair old worn screws by welding the flights

For screws with diameters larger than 60 mm, depending on the type of wear, it is possible to repair them by welding new material on the top of worn flights. This procedure can be applied only if there is no wear on the screw core or front-back flight radius, Important to mention is that a repaired screw will not last as long a new one. For further information about the welding alloys, please refer to the table below.

Welding materials for the screw flights

Refurbishing is a for larger units interesting for cost saving and delivery-time.

-

MM CODE

FLIGHT ARMORING

TECHNOLOGY

ABRASIVE WEAR RESISTANCE

CORROSIVE WEAR RESISTANCE

-

MM120Cobalt Base AlloyPTA++++++

-

MM50Iron Base AlloyTIG++++++

-

MM560Nickel Base AlloyPTA++++++++

-

MM570Nickel Base AlloyPTA+++++++++++

-

MM830Nickel Base AlloyPTA++++++++++

-

MM4900MolybdenumHVOF+++++++++

-

MM6000Tungsten CarbideHVOF++++++++++++

-

MM CODEMM120

-

FLIGHT ARMORINGCobalt Base Alloy

-

TECHNOLOGYPTA

-

ABRASIVE WEAR RESISTANCE+++

-

CORROSIVE WEAR RESISTANCE+++

-

MM CODEMM50

-

FLIGHT ARMORINGIron Base Alloy

-

TECHNOLOGYTIG

-

ABRASIVE WEAR RESISTANCE++++

-

CORROSIVE WEAR RESISTANCE++

-

MM CODEMM560

-

FLIGHT ARMORINGNickel Base Alloy

-

TECHNOLOGYPTA

-

ABRASIVE WEAR RESISTANCE++++

-

CORROSIVE WEAR RESISTANCE++++

-

MM CODEMM570

-

FLIGHT ARMORINGNickel Base Alloy

-

TECHNOLOGYPTA

-

ABRASIVE WEAR RESISTANCE++++++

-

CORROSIVE WEAR RESISTANCE+++++

-

MM CODEMM830

-

FLIGHT ARMORINGNickel Base Alloy

-

TECHNOLOGYPTA

-

ABRASIVE WEAR RESISTANCE+++++

-

CORROSIVE WEAR RESISTANCE+++++

Repair examples

Discover more products

Other products for injection and extrusion can be found below by clicking on the pictures more information is shown.

en

en nl

nl de

de it

it es

es