Nitridedcylinders

We offer a wide range of nitrided cylinder materials.

Hardened Cylinders

We offer a wide range of hardened cylinders for small diameters.

Bimetallic cylinders

Top grade of our solutions and commenly used are our bimetallic cylinders.

The advantage of our bimetallic alloys

The advantage of our bimetallic alloys is the high and homogeneous hardness throughout the whole layer thickness which ranges from 1.5 to 2 mm thickness. The lifetime increase of the bimetallic cylinder against a nitrided cylinder may exceed 12 times or more. The price-quality-lifetime ratio is therefore very beneficial for the bimetallic cylinder. We have five different alloy solutions listed in the table below. We qualified the quality of the different alloys according abrasion and or corrosion resistance to enable a quick selection.

The advantage of our nitrided and hardened cylinders

The nitrided cylinder obtains its wear resistance from a thin hard top layer of 0.3-0.4 mm applied by gas treatment, which is sufficient for standard polymers without fillers and has a good lifetime price ratio. For specific cases with small diameters, hardened materials can also be used.

-

MM code

Base Material

Treatment

Abrasive wear resistance

Corrosive wear resistance

-

MM31Quenced and TemperedNitriding++

-

MM41Quenced and TemperedNitriding++

-

MM34Quenced and TemperedNitriding++

-

MM39Quenced and TemperedHardening++++

-

MM codeMM31

-

Base MaterialQuenced and Tempered

-

TreatmentNitriding

-

Abrasive wear resistance+

-

Corrosive wear resistance+

-

MM codeMM41

-

Base MaterialQuenced and Tempered

-

TreatmentNitriding

-

Abrasive wear resistance+

-

Corrosive wear resistance+

Bimetallic alloys table

We qualified the quality of the different alloys according abrasion and or corrosion resistance to enable a quick selection. KB100/109 are general purpose alloys and KB300/350 are alloys for heavy wear applications. See also our material selector.

-

Type

Alloy

Alloy components

Hardness [HRC]

(a) Hardness of matrix, tungsten carbides have a hardness of 89 HRC.Abrasion resistance

(x good) to (xxxxx excellent)Corrosion resistance

(x good) to (xxxxx excellent) -

KB 100FeNi - C - B58 - 65+++

KB 100FeNi - C - B58 - 65+++ -

KB 109Fe - CrNi - Mo - Cu - C - B64 - 69++++++

KB 109Fe - CrNi - Mo - Cu - C - B64 - 69++++++ -

KB 200Ni - CoCr - Mo - B48 - 56++++++

KB 200Ni - CoCr - Mo - B48 - 56++++++ -

KB 300NiCr - Ni - Co - B - W60 - 66 (a)++++++++

KB 300NiCr - Ni - Co - B - W60 - 66 (a)++++++++ -

KB 350NiCr - Si - B - W60 - 66 (a)+++++++++

KB 350NiCr - Si - B - W60 - 66 (a)+++++++++

-

TypeKB 100

-

AlloyFe

-

Alloy componentsNi - C - B

-

Hardness [HRC]58 - 65

-

Abrasion resistance++

-

Corrosion resistance+

-

TypeKB 109

-

AlloyFe - Cr

-

Alloy componentsNi - Mo - Cu - C - B

-

Hardness [HRC]64 - 69

-

Abrasion resistance+++

-

Corrosion resistance+++

-

TypeKB 200

-

AlloyNi - Co

-

Alloy componentsCr - Mo - B

-

Hardness [HRC]48 - 56

-

Abrasion resistance+

-

Corrosion resistance+++++

Backing material table

Like 5 different bimetallic alloys, we also working with different backingmaterials. The selection for the right backing material is made on internal process pressure and cylinder design. The different material options garantee a flawless use of the cylinder.

-

Type

Yield point 300°C

Application

-

KB 25250 N/mm2Extrusion

-

KB 37370 N/mm2Extrusion

-

KB 63630 N/mm2Injection

-

KB 13130 N/mm2Extrusion

-

KB 48480 N/mm2Extrusion & Injection

Examples cylinders

Based on all material and treatment options we selected some examples screw configuration versus polymer processing.

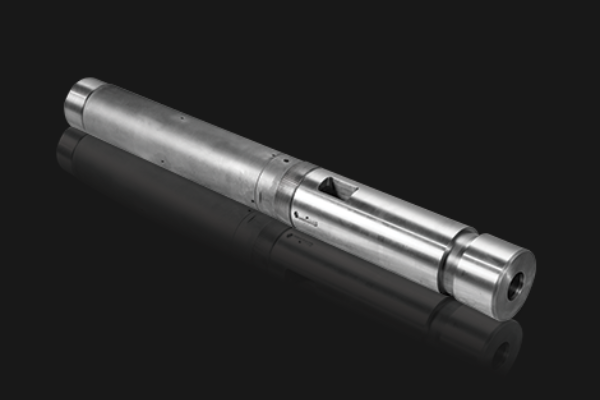

Nitrided Cylinder for polymers without or with low % fillers.

Nitrided Cylinder

Contact us-

Layer1,8509

-

Alloy componentsCr - Al - Mo

-

Hardness [HRC]950-1100 Hv (ca 65-67 Hrc)

-

Diameter [mm]Ø40

-

Abrasion resistance+

-

Corrosion resistance+

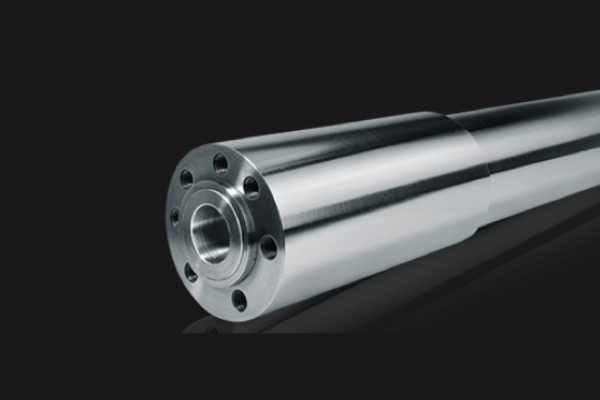

Bimetallic Cylinder for polymers with fillers till 30%.

Bimetallic Cylinder KB100/109

Contact us-

LayerKB100/KB109

-

Alloy componentsFe - Cr

-

Hardness [HRC]58 - 69

-

Diameter [mm]Ø 50

-

Abrasion resistance+++

-

Corrosion resistance+++

Bimetallic Cylinder for polymers with fillers above 30%.

Bimetallic Cylinder KB300/350

Contact us-

LayerKB300/KB350

-

Alloy componentsNi - Tungsten carbide

-

Hardness [HRC]60 - 66

-

Diameter [mm]Ø 35

-

Abrasion resistance+++++

-

Corrosion resistance++++

Discover more products

Other products for injection and extrusion can be found below by clicking on the pictures more information is shown.

en

en nl

nl de

de it

it es

es