Materials

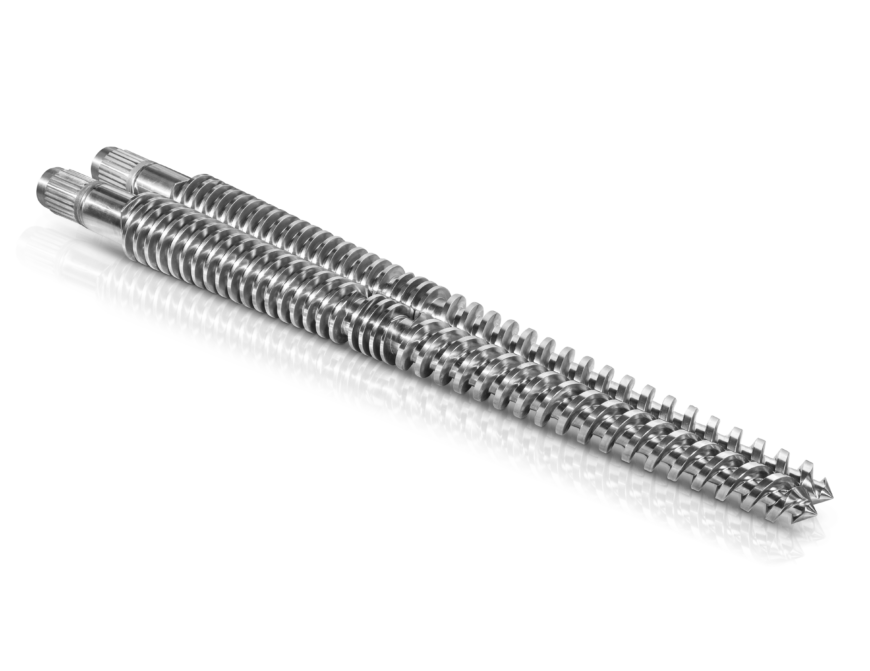

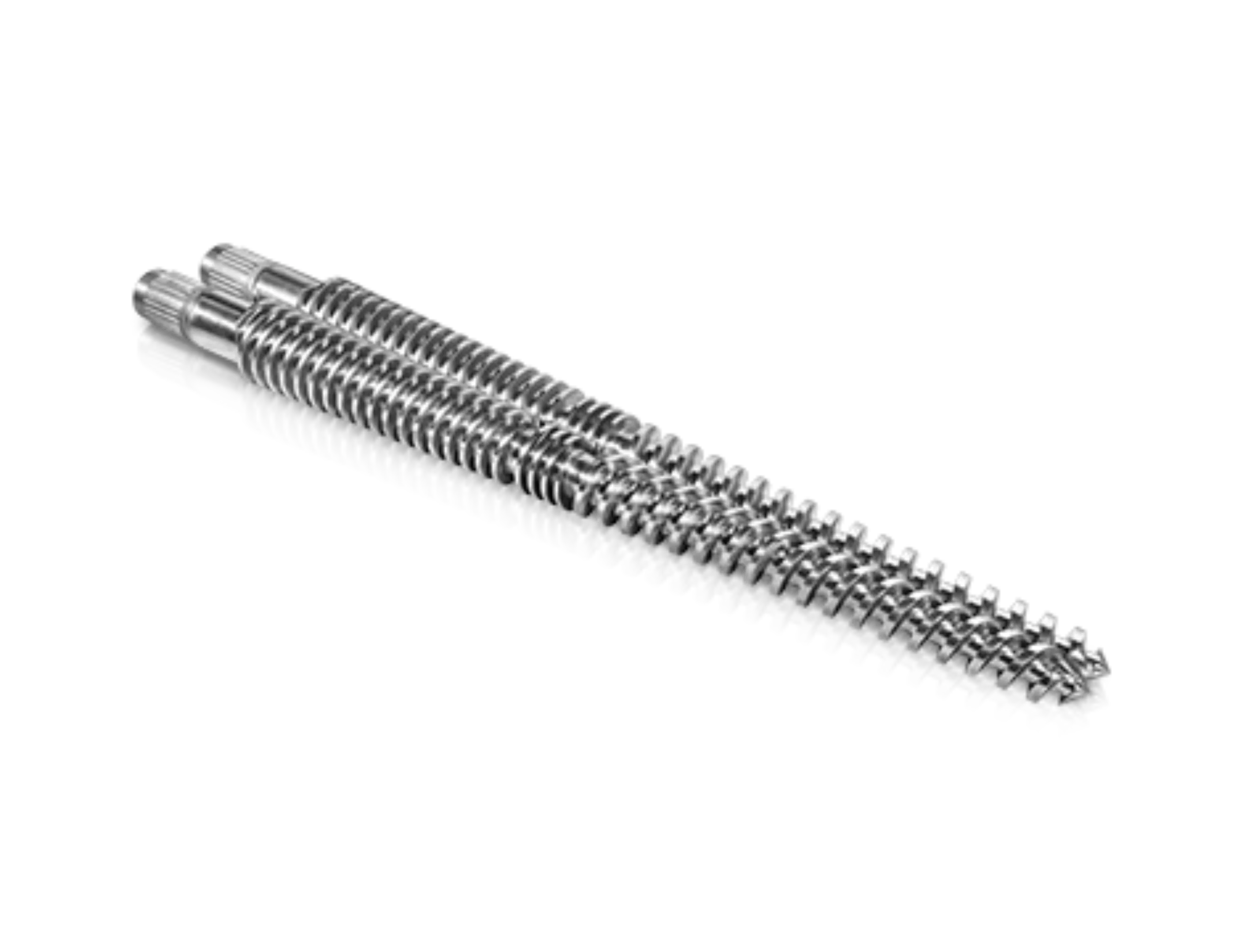

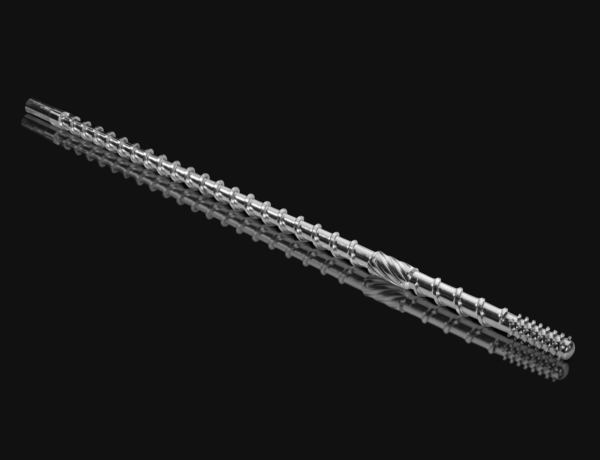

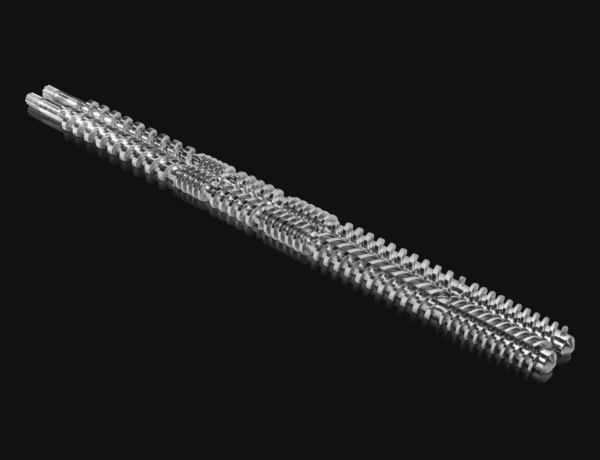

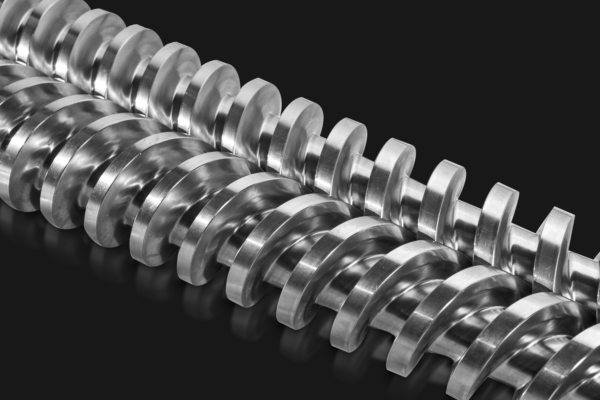

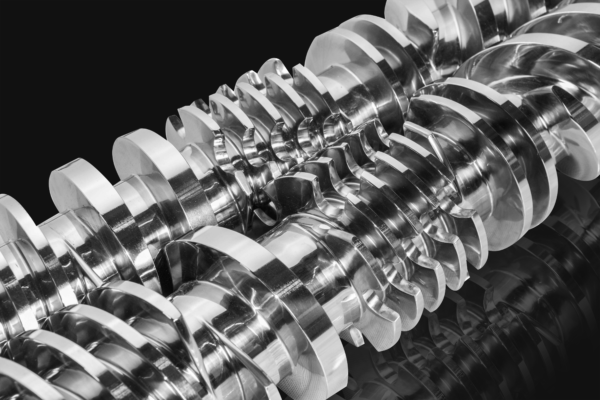

We can supply a complete range of conical twin screws. Based on our large experience we can recommend the proper type of steel and surface treatment to minimize wear. According to customer’s needs we can propose nitriding steel eventuallly welded with tool steel or other materials.

OEM’s specifications

We deliver screws according to OEM’s specification.The screwsare the heart of the process and determines the the productivity and the quality of the product.

Profiles

Maxi Melt can make screws with all kind of profiles which are in use with the customer.

Het voordeel van onze schroeven

Up to date machinery and CAD CAM facilities make it possible to manufacture high quality complex products with tight tolerances from different kind of materials to be selected from case to case with a high surface finish suitable to withstand wear and or corrosion conditions

Materials for plasticizing screws

Choosing the right screw material is important to have the right performance in order to reduce wear and corrosion problems

-

DIN standard

Base Material

Treatment

Abrasive Wear Resistance

Corrosive Wear Resistance

-

MM31Quenced and TemperedNitriding++

-

MM41Quenced and TemperedNitriding++

-

MM34Quenced and TemperedNitriding++

Welding materials for the screw flights

For extra protection we use high tensile strenght nitrided materials with welded flighttips. There are several material materials options. This is done to create wear/corrosion protecting or improve friction/lubrication

-

Type

Base Alloy

Alloy components

Hardness [HRC]

(a) Hardness of matrix, tungsten carbides have a hardness of 89 HRC.Abrasion resistance

(x good) to (xxxxx excellent)Corrosion resistance

(x good) to (xxxxx excellent) -

Stellite 1CobaltC - Cr - W52 - 57++++++

-

Stellite 12CobaltC - Cr - W44 - 48+++++

-

Colmonoy 56NickelC - Si - Cr - B - Fe52 - 56+++++++

-

Colmonoy 83NickelTungsten carbide56 - 60 [a]+++++++++

-

CastoTIG 5IronCr - V58 - 62++++++

-

TypeStellite 1

-

Base AlloyCobalt

-

Alloy componentsC - Cr - W

-

Hardness [HRC]52 - 57

-

Abrasion resistance+++

-

Corrosion resistance+++

-

TypeStellite 12

-

Base AlloyCobalt

-

Alloy componentsC - Cr - W

-

Hardness [HRC]44 - 48

-

Abrasion resistance++

-

Corrosion resistance+++

-

TypeColmonoy 56

-

Base AlloyNickel

-

Alloy componentsC - Si - Cr - B - Fe

-

Hardness [HRC]52 - 56

-

Abrasion resistance+++

-

Corrosion resistance++++

Welding materials for the screw flights

For larger screw sizes we often use nitrided materials with the flighttips welded welded with different materials options. This creates wear/corrosion protection or improves friction/lubrication.

-

MM CODE

FLIGHT ARMORING

TECHNOLOGY

ABRASIVE WEAR RESISTANCE

CORROSIVE WEAR RESISTANCE

-

MM120Cobalt Base AlloyPTA++++++

-

MM50Iron Base AlloyTIG++++++

-

MM560Nickel Base AlloyPTA++++++++

-

MM570Nickel Base AlloyPTA+++++++++++

-

MM830Nickel Base AlloyPTA++++++++++

-

MM4900MolybdenumHVOF+++++++++

-

MM6000Tungsten CarbideHVOF++++++++++++

-

MM CODEMM120

-

FLIGHT ARMORINGCobalt Base Alloy

-

TECHNOLOGYPTA

-

ABRASIVE WEAR RESISTANCE+++

-

CORROSIVE WEAR RESISTANCE+++

-

MM CODEMM50

-

FLIGHT ARMORINGIron Base Alloy

-

TECHNOLOGYTIG

-

ABRASIVE WEAR RESISTANCE++++

-

CORROSIVE WEAR RESISTANCE++

-

MM CODEMM560

-

FLIGHT ARMORINGNickel Base Alloy

-

TECHNOLOGYPTA

-

ABRASIVE WEAR RESISTANCE++++

-

CORROSIVE WEAR RESISTANCE++++

-

MM CODEMM570

-

FLIGHT ARMORINGNickel Base Alloy

-

TECHNOLOGYPTA

-

ABRASIVE WEAR RESISTANCE++++++

-

CORROSIVE WEAR RESISTANCE+++++

-

MM CODEMM830

-

FLIGHT ARMORINGNickel Base Alloy

-

TECHNOLOGYPTA

-

ABRASIVE WEAR RESISTANCE+++++

-

CORROSIVE WEAR RESISTANCE+++++

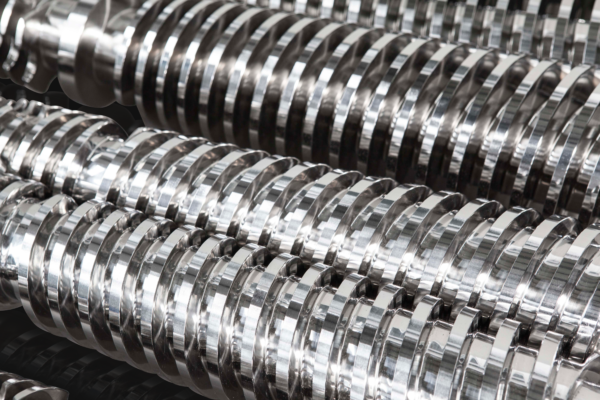

Voorbeeld schroeven

Based on all material and treatment options we selected some examples screw configuration versus polymer processing.

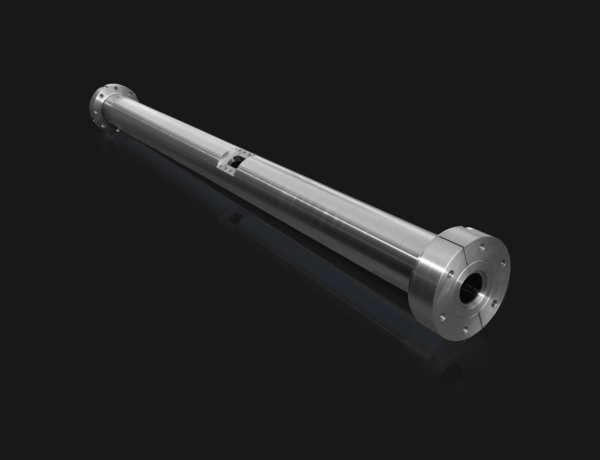

Discover more products

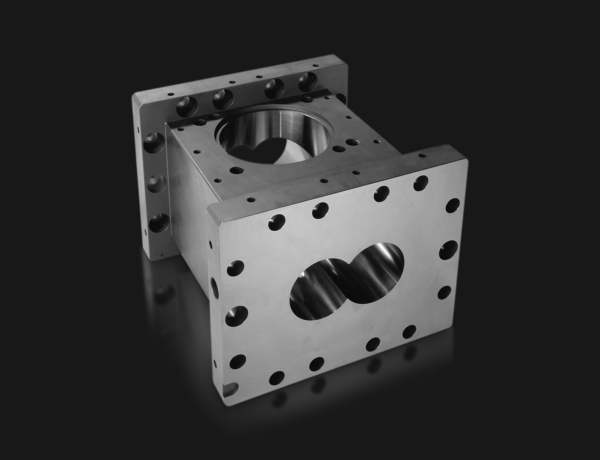

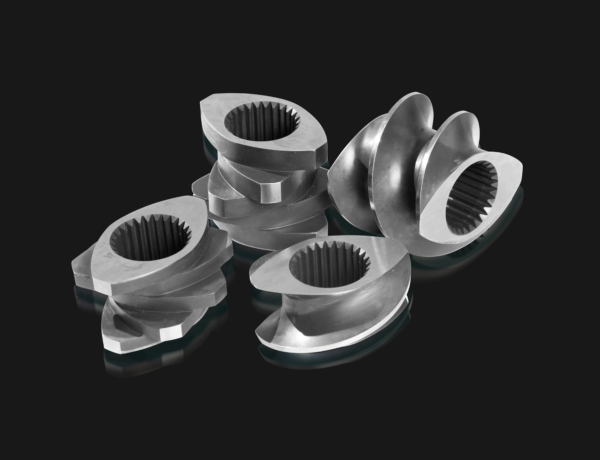

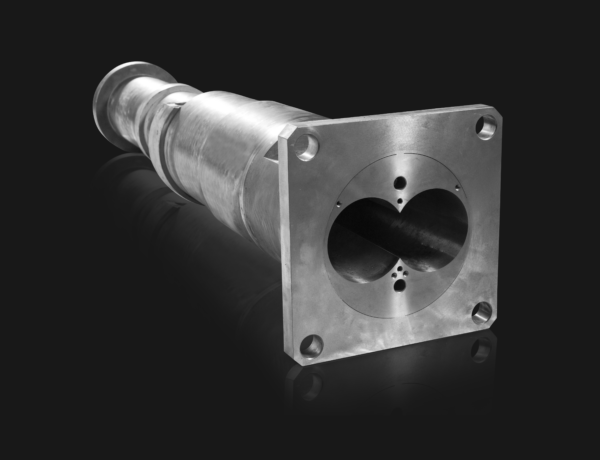

Other products for injection and extrusion can be found below by clicking on the pictures more information is shown.

en

en nl

nl de

de it

it es

es