Wear solution

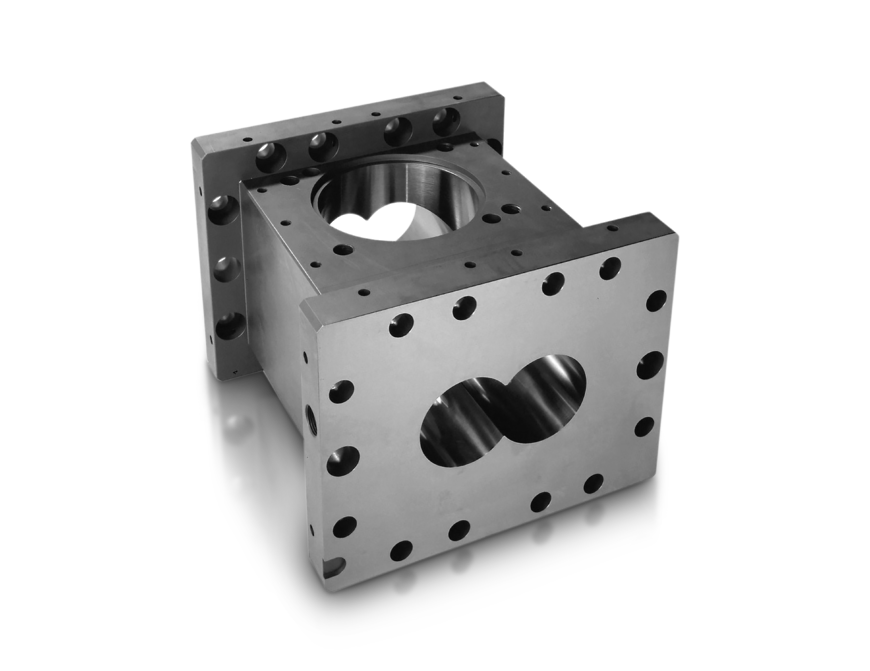

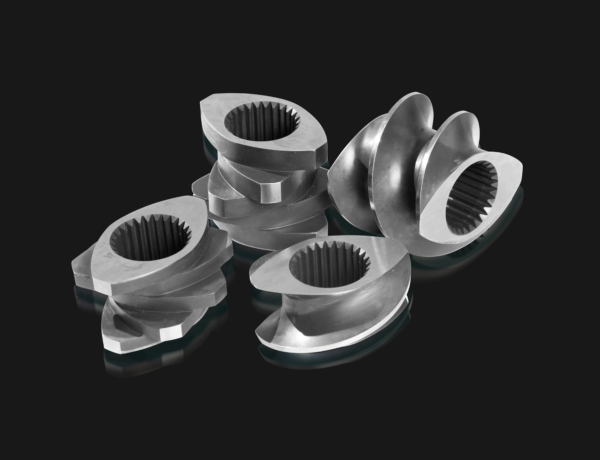

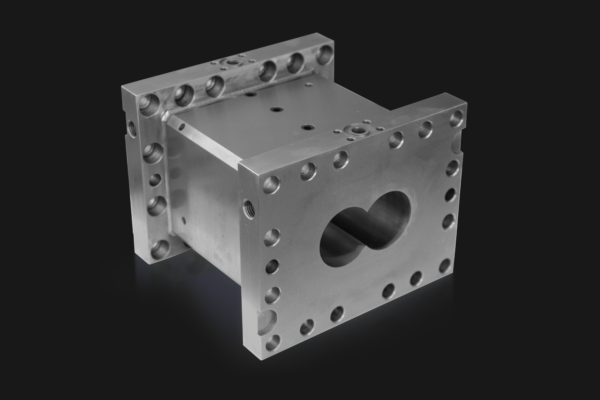

We can supply a complete range of twin blocks. Based on our large experience we can recommend the proper type of steel and surface treatment to minimize wear. According to customer’s needs we can propose nitriding steel, tool steel and also sintered steels (CPM/PM).

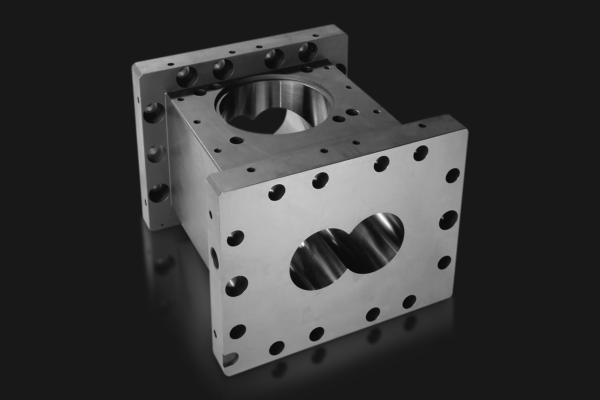

Twinblocks according to OEM’s specifications

We deliver twin blocks according to OEM’s specification.

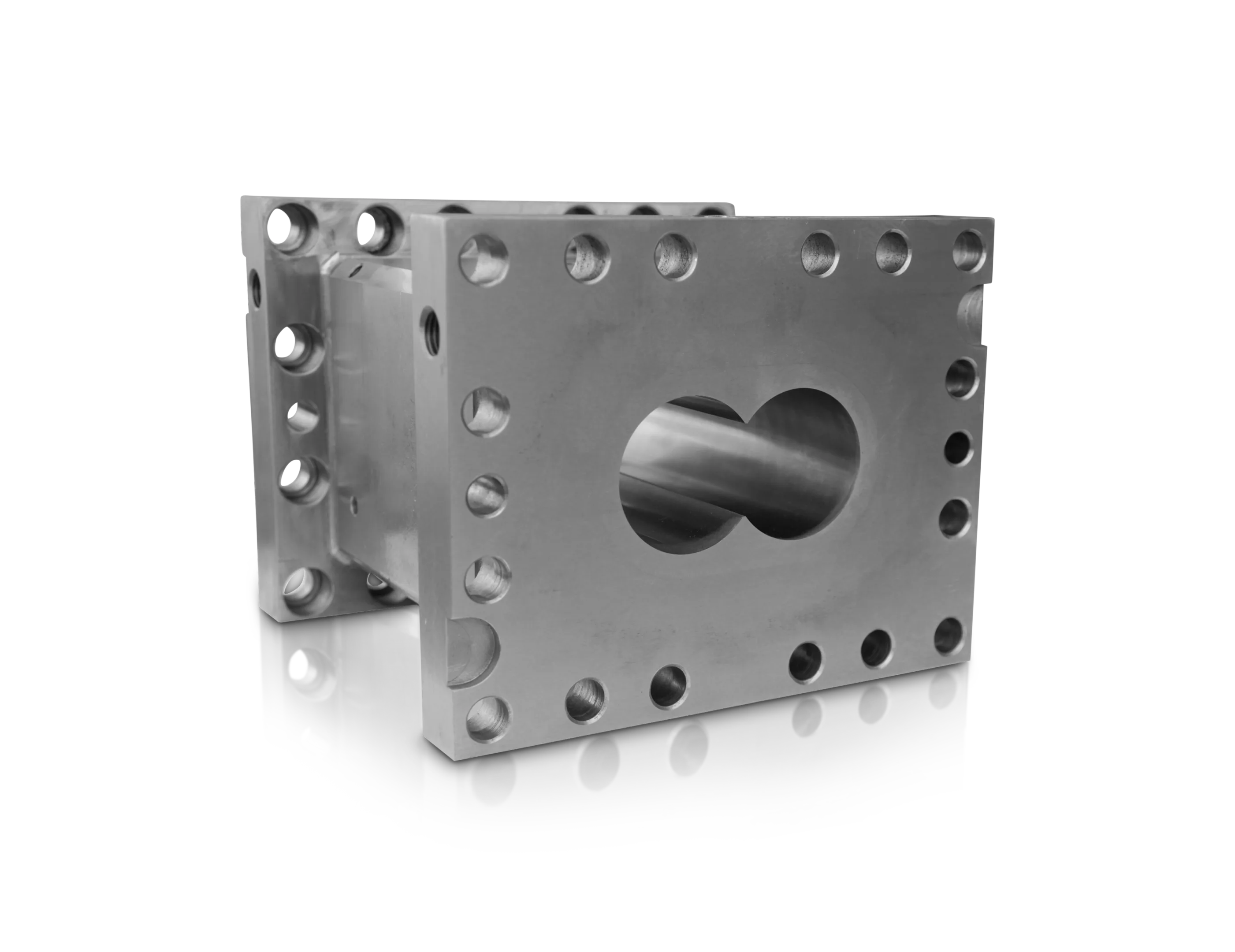

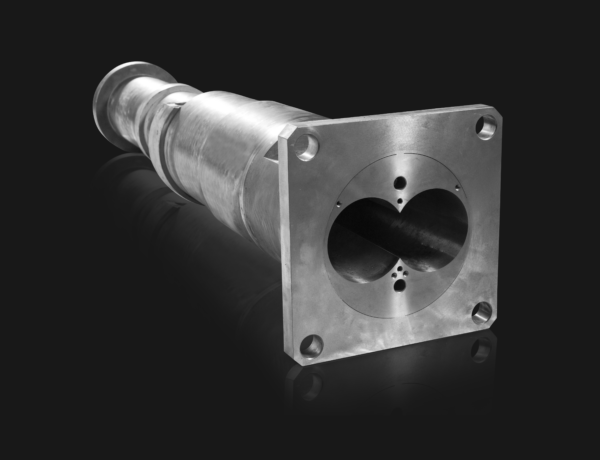

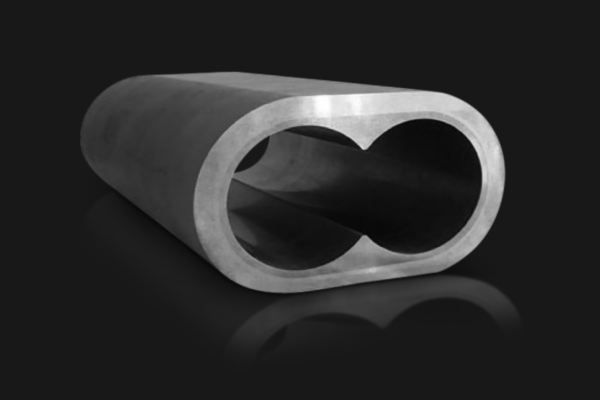

Ovalliner replacement

Maxi Melt offers replacement services from old worn oval section.

The advantage of our twin blocks

Up to date machinery and CAD CAM facilities make it possible to manufacture high quality complex products with tight tolerances with a high surface finish suitable to withstand wear and or corrosion conditions.

Double housing/oval materials

Choosing the correct Double Housing/Oval material is important to achieve the correct performance and reduce wear and corrosion.

-

MM Code

Base Material

Treatment

Abrasion resistance

(x good) to (xxxxx excellent)Corrosion resistance

(x good) to (xxxxx excellent) -

MM41Quenced and TemperedNitriding++

-

MM34Quenced and TemperedNitriding steel++

-

MM121Cold work to SteelHardening+++++

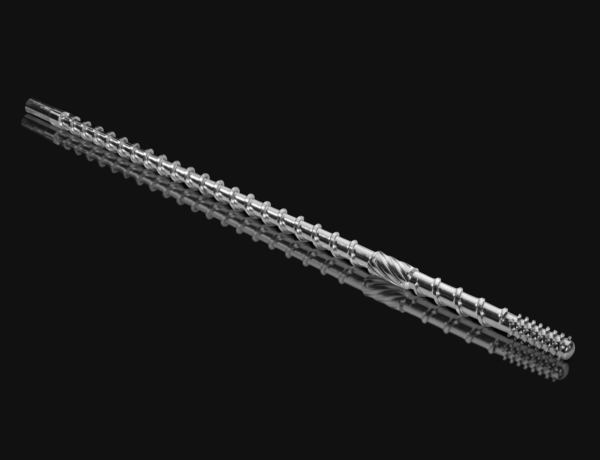

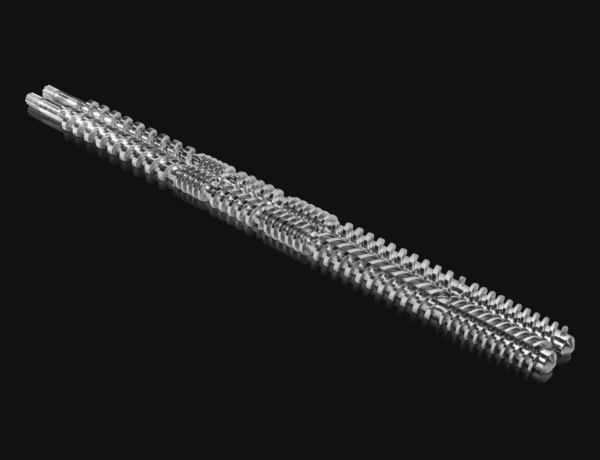

Example Twin block co

Based on all material and treatment options we selected some examples for twin corotating processing.

Twin block co. solid made from standard material.

Twin block co 1

Contact us-

Alloy1,8509

-

Alloy componentsCr - Ai

-

Hardness [HRC]950-1100 Hv (65-67 Hrc)

-

Size [mm]Ø 60

-

Abrasion resistance+

-

Corosion resistance+

Twin block co. with hardened oval section.

Twin block co 2

Contact us-

Alloy1,2379

-

Alloy componentsCr Mo

-

Hardness [HRC]59-63

-

Size [mm]Ø 75

-

Abrasion resistance+++

-

Corosion resistance++

Twin block co. Hardened KPM1/2 oval section.

Twin block co 3

Contact us-

AlloyKPM 1/2

-

Alloy componentsPowder metallallurgical

-

Hardness [HRC]55-63

-

Size [mm]Ø 60

-

Abrasion resistance+++++

-

Corosion resistance+++++

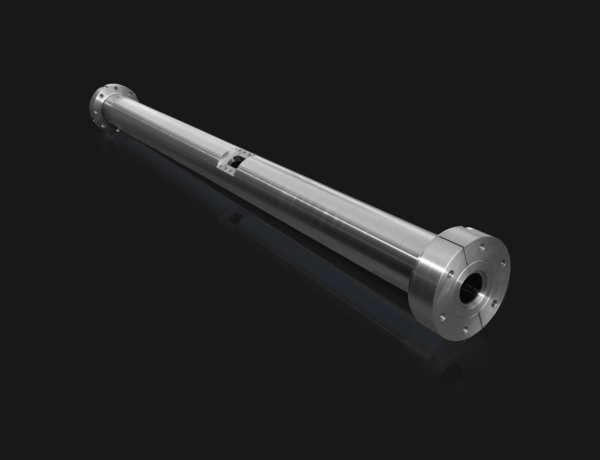

Discover more products

Other products for injection and extrusion can be found below by clicking on the pictures more information is shown.

en

en nl

nl de

de it

it es

es